PROGRAMMABLE HAPTIC KNOB FOR L5 AUTONOMOUS VEHICLES

Developing a patented, single point of control and interaction for GM's dashboard system in an L5 autonomous vehicle that provides haptic, ergonomic feedback based on user task and input.

role: Project Manager, Product Designer

The internal knob design is undergoing the patent application process with General Motors and cannot be shown. The following information provides a general overview of this project.

PROJECT CONTINUATION

Our team worked with the GM-GT HMI Lab as a continuation of their existing research and development for GM into potential vehicle applications. Previous researched lacked user validation and product design, which dictated our project goals in providing this data for the patent application process.

DEFINING THE FUTURE GENERATION

Following research into the future of autonomous vehicles, our team defined the current generation of commuters as the most probable adopters of this new technology using the projection of 2035 as the year autonomous vehicles enter the market. Our survey of this user group defined the expectations and use cases of our product in an L5 vehicle environment.

TASK DISTINCTION

Based on survey findings, user needs for haptic output were divided into three general categories: work tasks and relaxation tasks.

WORK MODE

RELAXATION MODE

BASELINE ACTIVITY

USER FLOW SCREENS

Using the existing open-source haptic code, our team modified its input to map directly into our screen prototype keybinds in FIGMA. I created three interfaces for each of the task distinctions for users to walk through during testing. Using biometric data to calculate cognitive load levels per task, our team used this data to justify and make modifications to our haptic feedback controls.

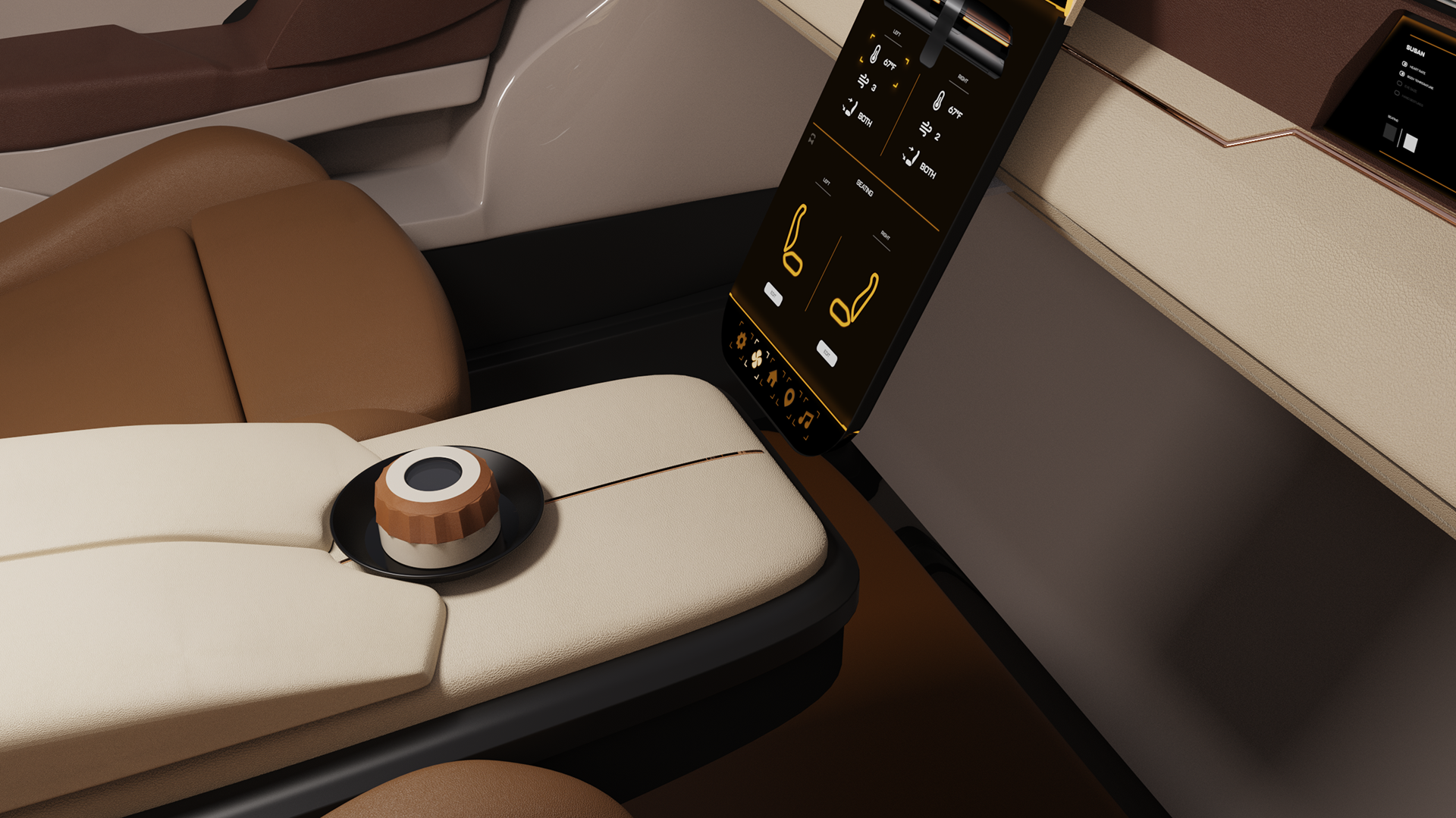

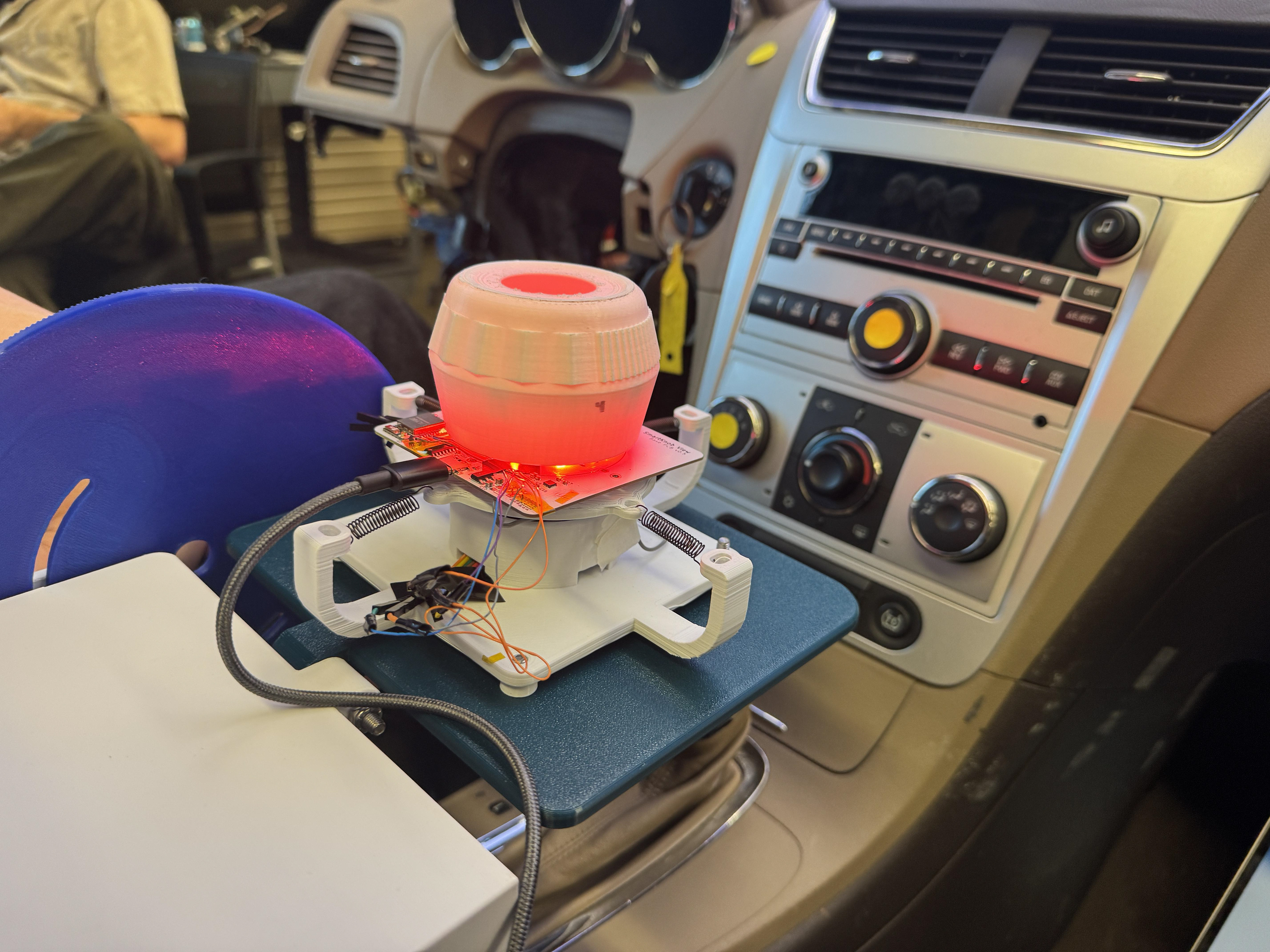

TESTING ENVIRONMENT

To simulate the interior of an L5 autonomous vehicle, we set up an OLED dash display on a modified Chevy Malibu, removing its steering wheel and adding in cameras to record biometric data. We mounted the haptic knob onto the center console per the original design.

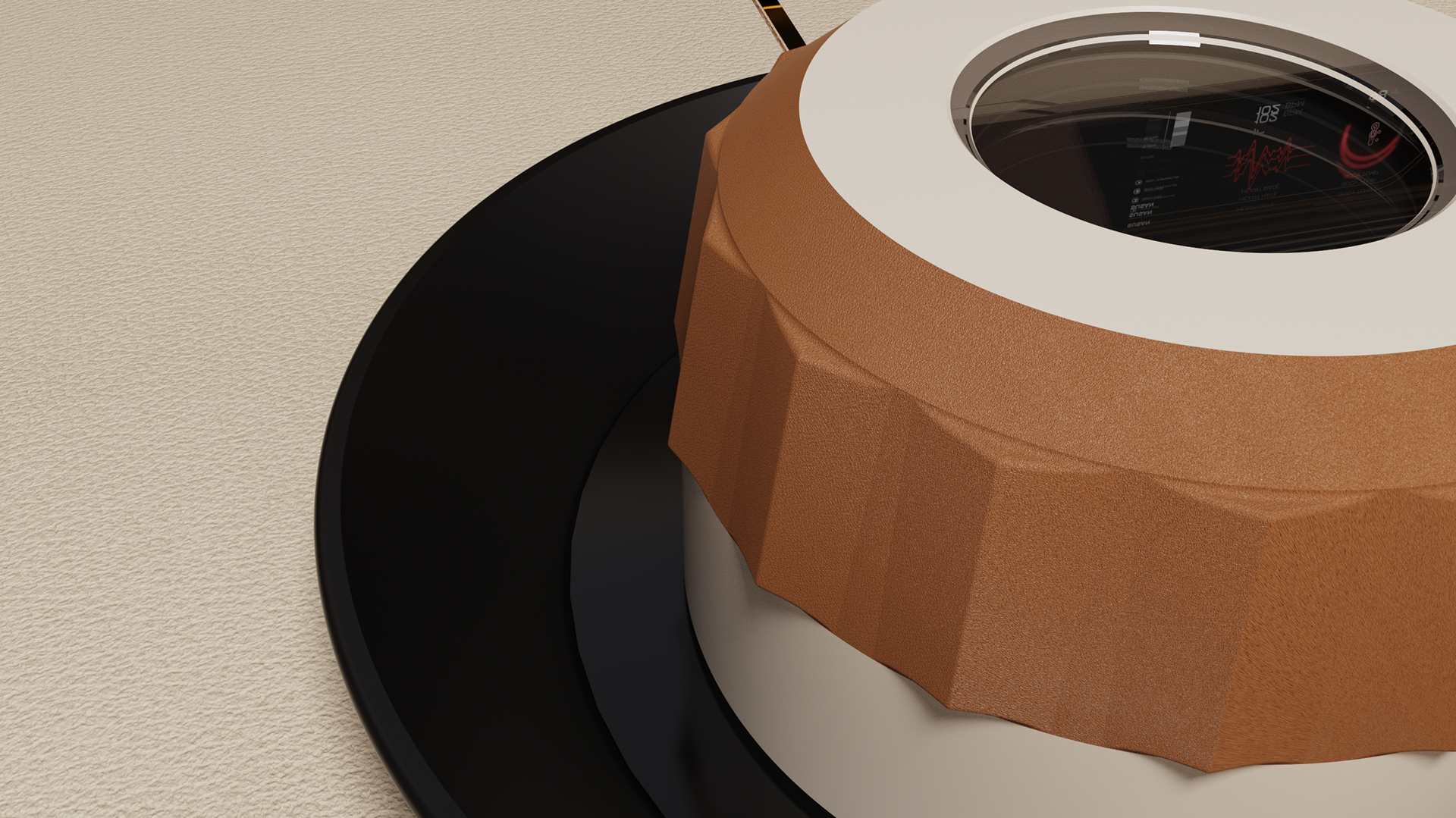

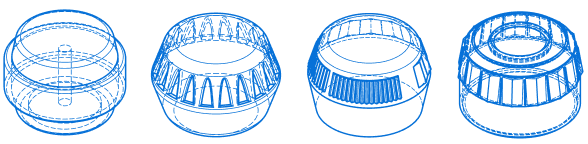

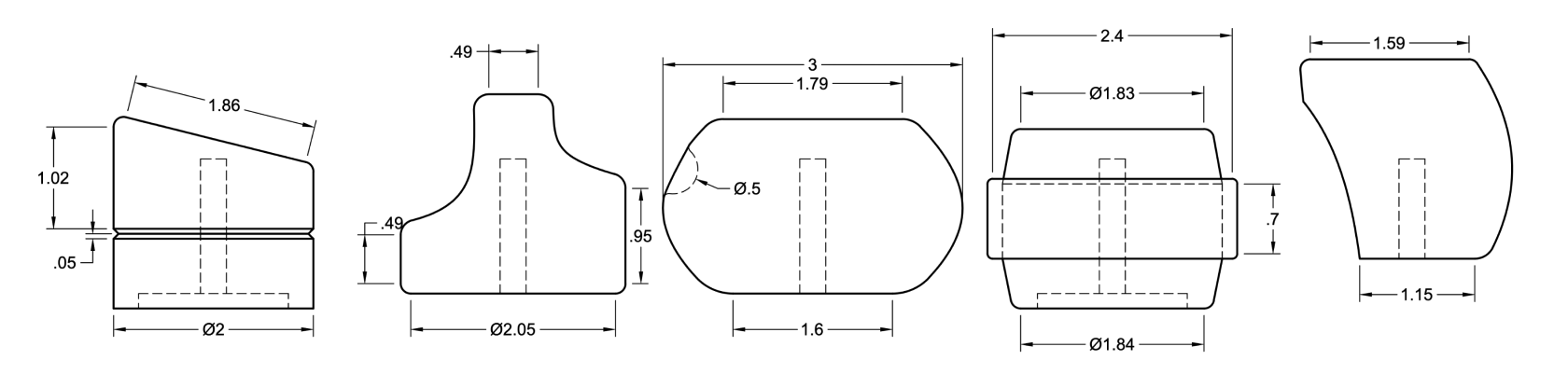

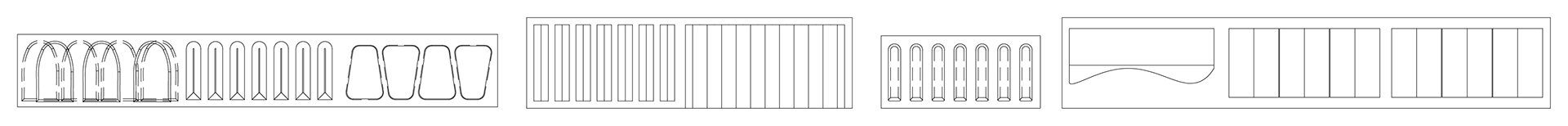

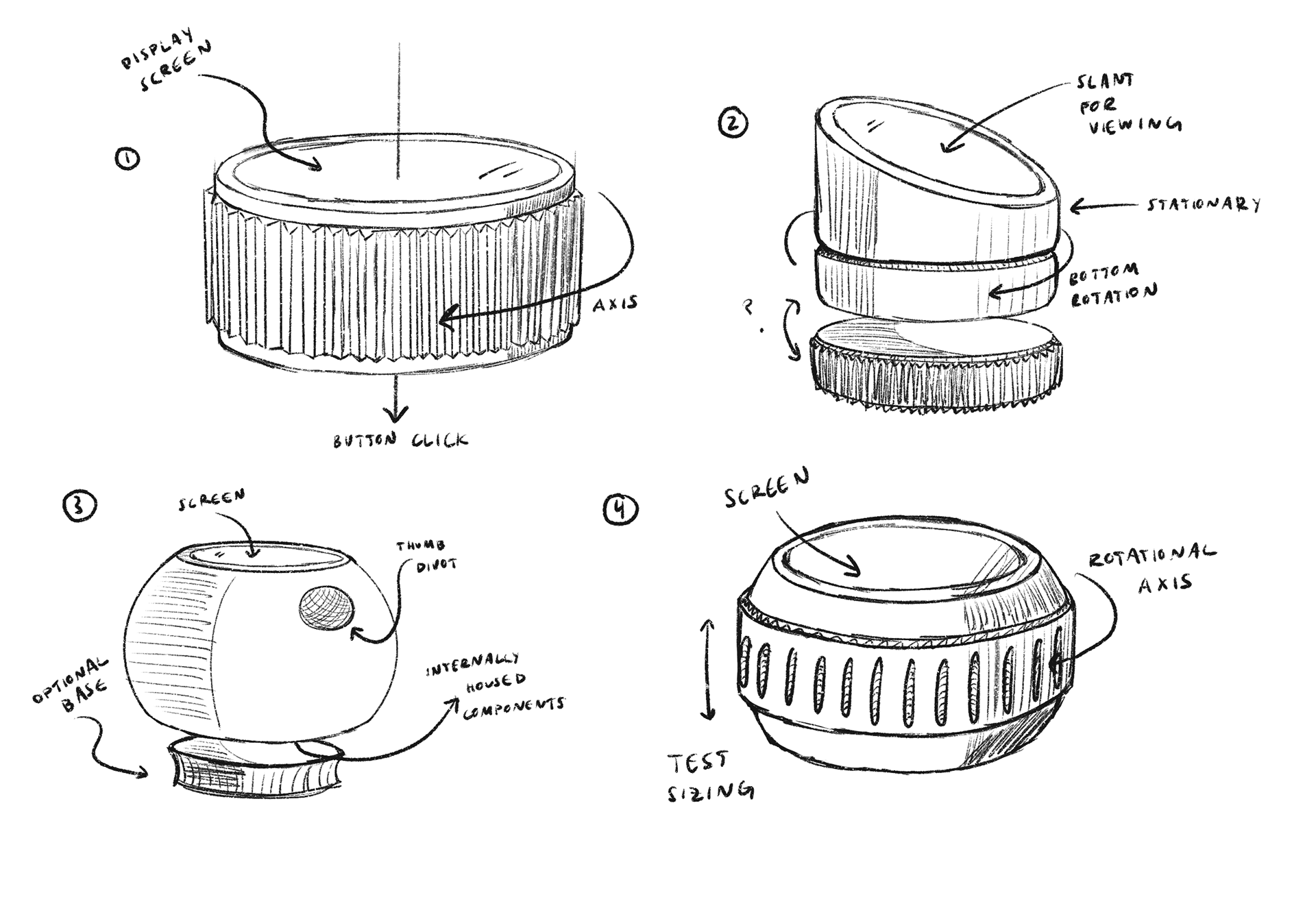

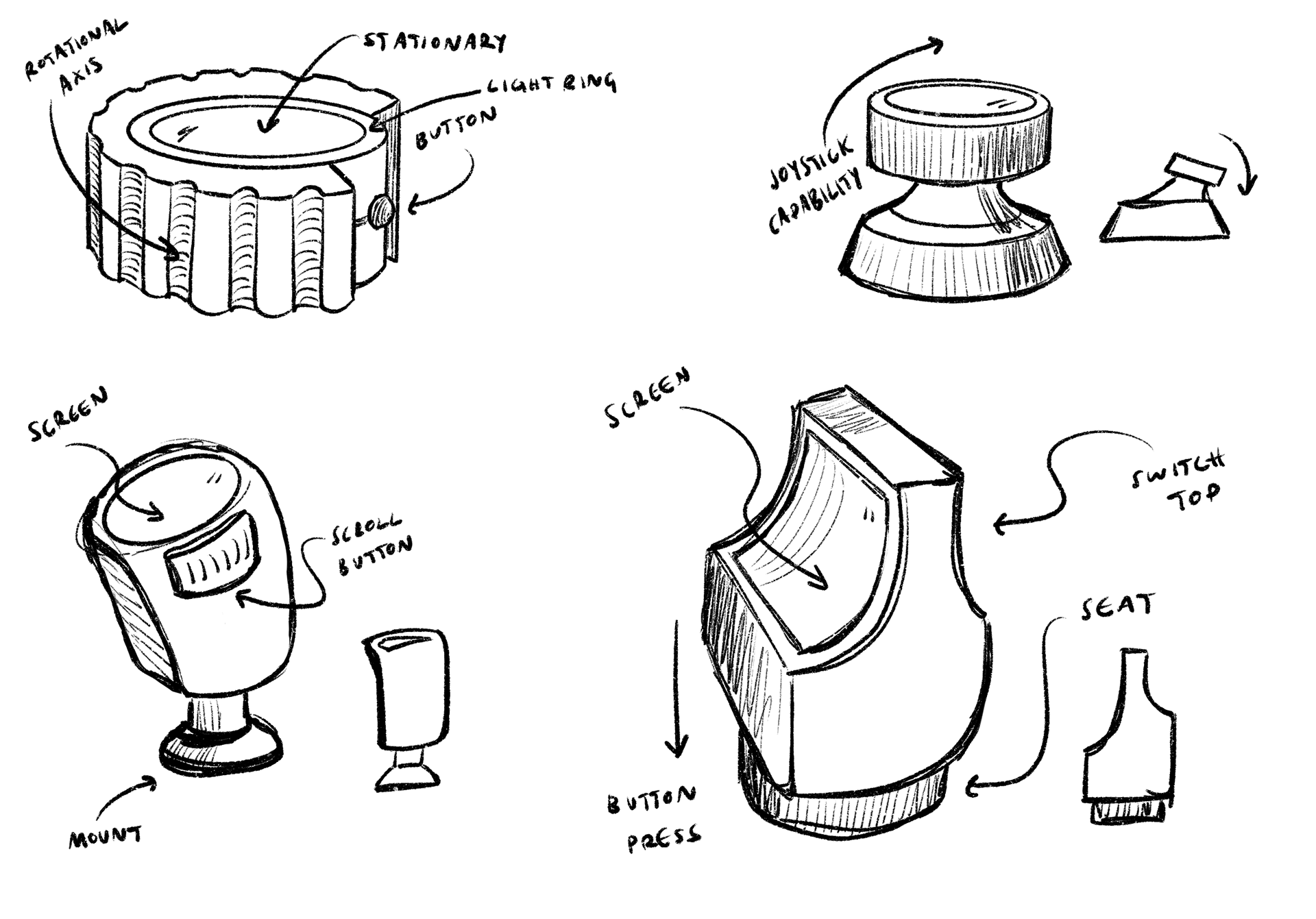

FORM DEVELOPMENT

Alongside the internal electrical changes made by the engineering department, I conducted separate rounds of user testing for the external knob shell. Based on NASA and Humanscale documentation of ergonomic design, this iterative process refined the final knob texture and taper angles. Our working prototype uses 3D-printed materials and a customizable TPU texture.

DESIGN FOR MANUFACTURING

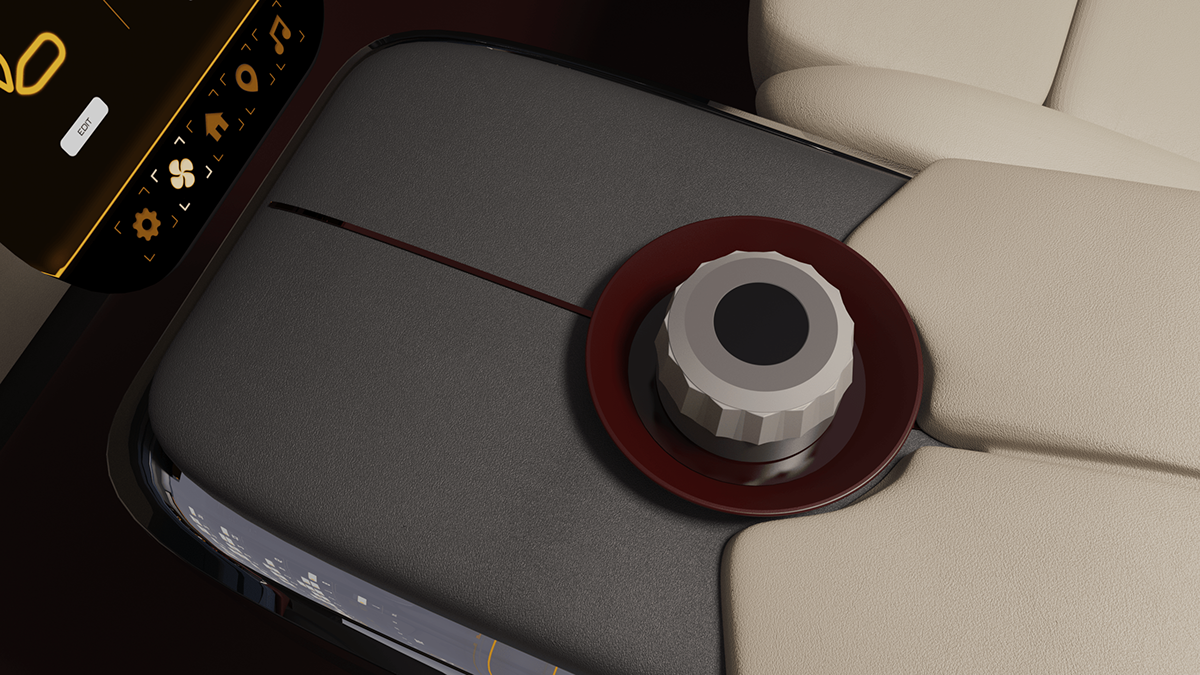

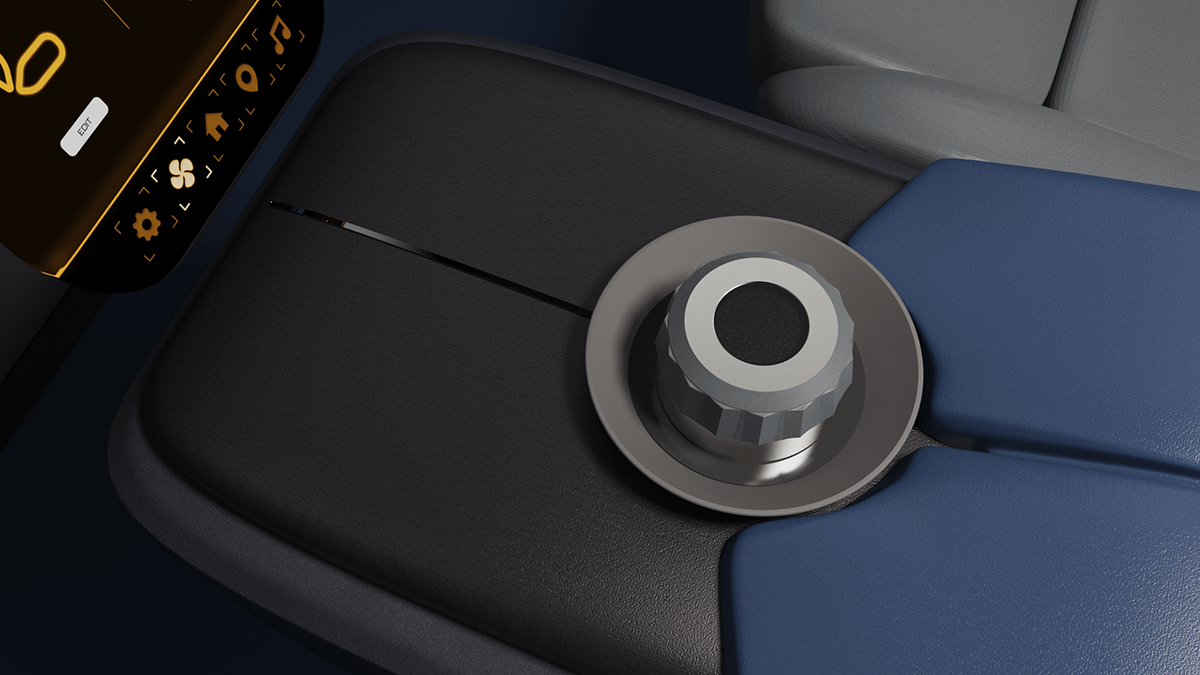

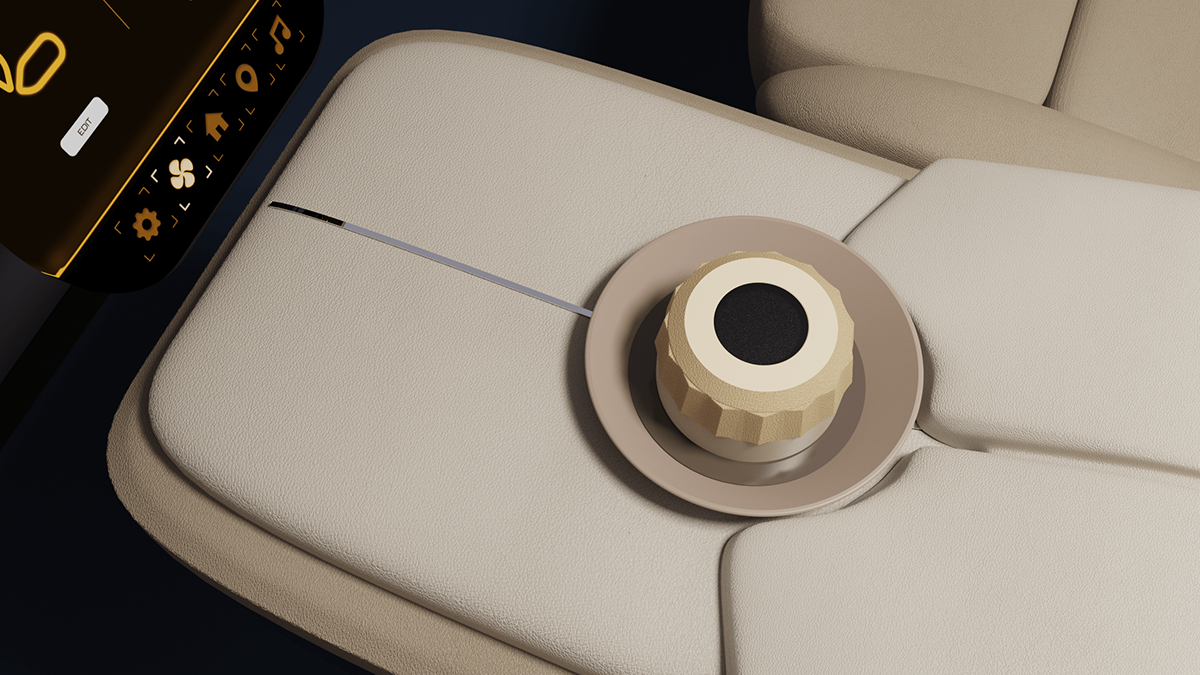

All haptic knob components were designed to fit industry manufacturing standards for mass production injection molding. The final plastic surfacing texture are aligned with Mold-Tech, which allows manufacturers to define their own preferences for the final design. Our team provided multiple colouring options to GM to match their current line of car interiors.

ENVIRONMENTAL DESIGN

Our team provided additional design updates for durability and environmental protection tailored to automotive interiors. We selected waterproof outer materials, added in silicone o-rings and glass covers into the BOM to protect the electronic components. Our stress tests on each assembly part revealed its ability to sustain up to 70 pounds of direct applied force.